Case Study

Timehouse works with Kontio, the world’s largest log manufacturer, to integrate BIM workflows across the organisation

- C++ programming language

- Lua script

- GDL script

- Javascript

- ERP, PLM and CRM integrations

Find out how Kontio’s cutting-edge log manufacturing is supported by Timehouse BIM customisations, and how an integration beyond BIM is ushering in a new age of log element manufacturing.

Customer & collaboration

Kontio, based in Finland, are the biggest log home manufacturer in the world. They are innovators and leaders in sustainable building at-scale. Drawing on their log building heritage, Kontio is now also known for its innovative Kontio Glass House.

How was Timehouse selected as a partner?

Timehouse was selected as Kontio’s software development partner due to our ArchiLogs and ArchiFrame experience and track record in customising Archicad add-ons.

Challenge

A pioneer in log home manufacturing, Kontio needed a software package to work with its own unique production processes. As well as customisations for the production line, Kontio needed a way to share log data with the rest of its commercial operations.

Kontio uses Archicad, ArchiFrame, and ArchiLogs. When aligning this software package with Kontio’s in-house production line, Kontio’s Project Lead, Samuli Kokko, quickly realised that extensive customisations were needed. Samuli is Kontio’s super user and coordinates all Kontio’s in-house Archicad, ArchiFrame and ArchiLogs users (about 30-40 in total).

Samuli explains how choosing the software was about investing in a finished BIM product, yet still being able to customise it to get something truly industry-leading: “The need for customisations is driven by the production line. On the production line, we are constantly working towards greater harmony and standardisation, borrowing lessons from concrete element production. We want to be part of the standardisation drive and help drive the log industry forwards.”

Solution

Crucial changes were made to the software so that internal Kontio terms and processes were respected and reflected. We implemented important ArchiLogs customisations (read more about it here in our blog) so that Kontio’s proprietary log ends, machinings, connectors, notches etc. could be found inside the software. An important feature was the creation of a new library object in GDL: a beam that would work in the innovative Kontio Glass House.

Software Architect Kristian Töyrä explains how making the software work for Kontio included “the addition of extra features not previously available in the software, as well as custom configuration so that Kontio essentially has its own version”. Harmonisation between ArchiFrame and ArchiLogs was something that Samuli Kokko saw as “essential”, as this would allow beam, truss, and other wood elements to be aligned with log elements. Creating an all-in timber construction system unique to Kontio brings many benefits as Samuli muses, “now we can really own and refine the process from start to finish”.

“Communication is the main thing, and that has worked well. Timehouse and the team have done a lot of hard work to ensure that projects stay on track. We all work together well, and I can focus on software adoption on our end.”

CNC data was also modified so that it could be exported in the correct format, ensuring Kontio’s CNC machines worked efficiently. Kontio has historically had a variety of CNC machines in-house, and it was important to prioritise the production line in software development. With the new changes, in-house labelling was respected and machinings made in a way that worked for Kontio. Automation was implemented in an iterative way and the production line could continue as usual, only better.

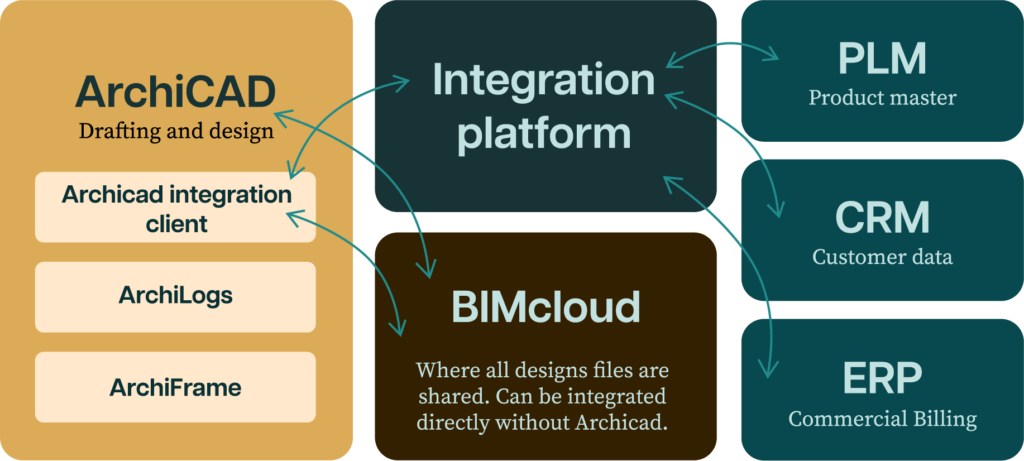

A big ongoing project is the integration of BIM data deeper into Kontio systems. Going beyond CNC and element production, this is about the flow of BIM and log data into ERP, PLM and sales software and systems:

“The vision is to take geometric data directly from the model all the way to PLM software, to our product master. We want to use enriched data and mine it for future opportunities. By enriching the data model, not only can we embrace the concept of digital twins when it comes to the model, but we can also create digital twins of the actual modelling and production processes.”

This ongoing integration project is only step one in a long process towards end-to-end digitalisation, and it’s exciting to see Kontio’s drive innovation in this arena.

The Timehouse-Kontio collaboration has been very intensive and extensive, and Samuli feels that Timehouse has a good understanding of Kontio’s needs:

“Communication is the main thing, and that has worked well. Timehouse and the team have done a lot of hard work to ensure that projects stay on track. We all work together well, and I can focus on software adoption on our end.”

Samuli works with the product development team, production line, and in-house users, and has a busy time prioritising what needs doing next. When it comes to speaking to the Timehouse team, good communication is supported by good documentation, project leadership, and transparency.

“It’s been a good co-operation with good experiences of working with different people. Communication has always been easy, and as we have been able to come together around the same table on multiple occasions, we have been able to sort things out quickly.”

In a nutshell

- C++ programming language

- Lua script

- GDL script

- Javascript

SAP integration with Archicad (ERP)

Sovelia integration with Archicad (PLM)

Salesforce integration with Archicad (CRM)