Earlier this autumn, we went up to Oulu to visit the Kontio team to kick off our joint log optimisation pilot project.

We’re developing an optimisation algorithm that estimates how much waste will be generated from shaping log blanks during the design phase, optimising log cuts for timber efficiency. Optimised logs can then be exported to CNC and be sent straight from design to production.

Partially funded by Business Finland, this pilot project will help us understand the needs of log element designers in more granular detail and expand how BIM data can be harnessed production.

In the room, we had the Timehouse BIM team, Kontiotuote CTO, Mikko Löf, Project Manager, Samuli Kokko, Product Development Engineer, Tuomo Vattula, and Timo Pesiö and Jussi Mäntylä from the Kontiotuote production line. Here’s what we can share about the project so far…

What does our log optimiser look like?

Initially tabled in discussions back in 2021, the log optimisation software we create will:

- Give designers the ability to cut back on waste during the design phase by optimising log cuts and assembling logs in the most waste-efficient way.

- Give designers the ability to place log cuts in specific places.

Our algorithm will decrease waste generated by cutting log blanks during the design phase. The algorithm will calculate how to cut from logs raw timber to maximise efficiency, showing the log designer the most efficient places to cut and join logs.

The log designer will also be given the opportunity to place log joins in practical locations e.g. interior walls.

What are the goals of this project?

We want to help log builders, and eventually, other timber builders, to:

- Reduce waste

- Build more efficiently.

In terms of tangible figures, let’s say that currently 5% of the logs run through your production line end up as waste; even a 1% reduction in waste can bring significant savings.

We want the relationship between model and production output to be as integrated as possible; production and design optimisation go together with our solution.

Our log optimiser in more detail

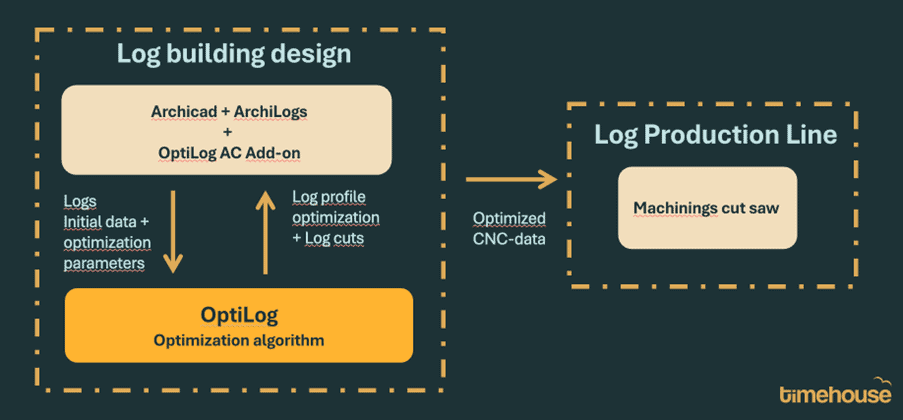

Eventually, we want to expand our offering. This is a current diagram of how the software will work if you are using Archicad:

The algorithm we have developed optimises the use of materials during the structural design phase. Our solution will enable optimisation across the construction lifecycle: nowadays, optimisation often happens later on, or in post-production.

- Smart → the automated algorithm considers production, design, and logistics, as well as technical and aesthetic requirements.

- Adaptive → The algorithm’s preferred optimisation parameters can be fully customised on a customer basis. The algorithm is also suited to different materials.

- Compatible → can be integrated with various design software.

The optimiser will adapt to your production needs. You can adjust log blank measurements, saw settings, and design parameters. You can also adjust the optimisation process and re-run the optimisation whenever you need to further refine results.

Note: we can work in a variety of software environments.

Why this project matters?

Waste generated during timber construction processes puts a stress on natural resources and increases emissions and costs. Some waste is inevitable, but everything should be done to minimise waste as timber is an expensive resource.

The structural design phase plays a crucial role in waste reduction, though successfully reducing waste requires a comprehensive examination of the production process.

Manual methods of optimisation are slow, and errors get magnified across the construction lifecycle. This optimisation algorithm empowers designers to take control and streamline optimisation.

Benefits of the optimiser:

- Less waste = lower costs and smaller CO₂ emissions

- Supports sustainability goals and sustainable building

- Fast and automatic optimisation process.

Why Kontio are the best partners for this project

We have already worked together on multiple BIM projects such as ArchiLogs customisations and an Archicad integration project and have an understanding and mutual trust that allows us to get deep into the production workflow.

Meeting in person and seeing the factory and production plant in action gives us a more tangible grasp on what our optimiser is being used for.

It is great to have such a close relationship with Kontio and meet in person. We always enjoy sharing ideas with Kontio: an innovative log home design brand run by people passionate about sustainability.

What does the future look like

Our goal is that by 2027, we will have an optimiser ready for the market, possibly with different levels of service. We want to be part of building more sustainably, both environmentally and commercially.