We are very pleased to be collaborating with Mikko on our BIM development projects and excited to offer his practical expertise to our clients! We sat down with Mikko to get his take on current log and timber construction industry trends and opportunities for future development.

Meet Mikko Kyläkoski: log design expert

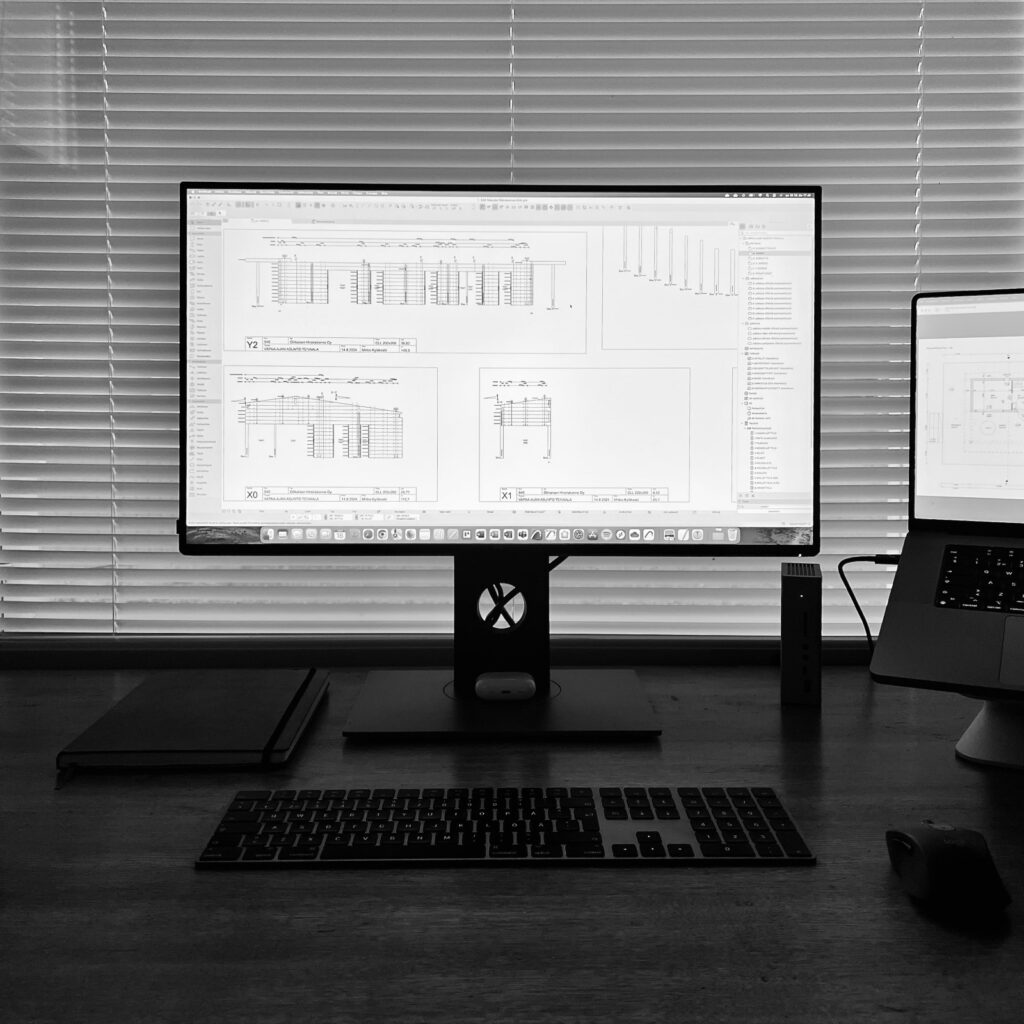

Mikko Kyläkoski is a wood and timber technology engineer who specialises in the design of log buildings and has actively participated in the development of log design software. Mikko has also worked in architectural offices and a construction company in information modeling.

What makes log and timber engineering special?

For Mikko, “thanks to growing up in the countryside among many log and wood buildings, logs have always seemed like the most natural building material to me”.

Log building goes beyond great materials: log houses have a structural clarity to them. The unique design challenges and characteristics of log buildings have long fascinated Mikko: “with natural resources like logs, the designer is given certain strict parameters that must be translated into architectural drawings. In this context, design work is a type of creative problem-solving”.

In a challenging and dynamic industry such as log building, continuous software development is essential to meet changing demands.

Logs are a renewable resource

Timber construction is often marketed as an alternative to less sustainable building practices and, especially in the Nordics, timber engineering has contributed positively to the built environment over the past decades.

“The use of renewable natural resources is becoming more important every year, and log buildings offer healthy and long-lasting living environments. It is important that timber and log construction keep up with industry and planning developments. I feel that by promoting wood construction, I have done my small part to take care of the planet we live on”.

What opportunities come from combining tech and timber building?

Mikko is positive about the possibilities offered by timber construction technology as he’s seen how the software on the market has developed and expanded capabilities alongside the timber building industry.

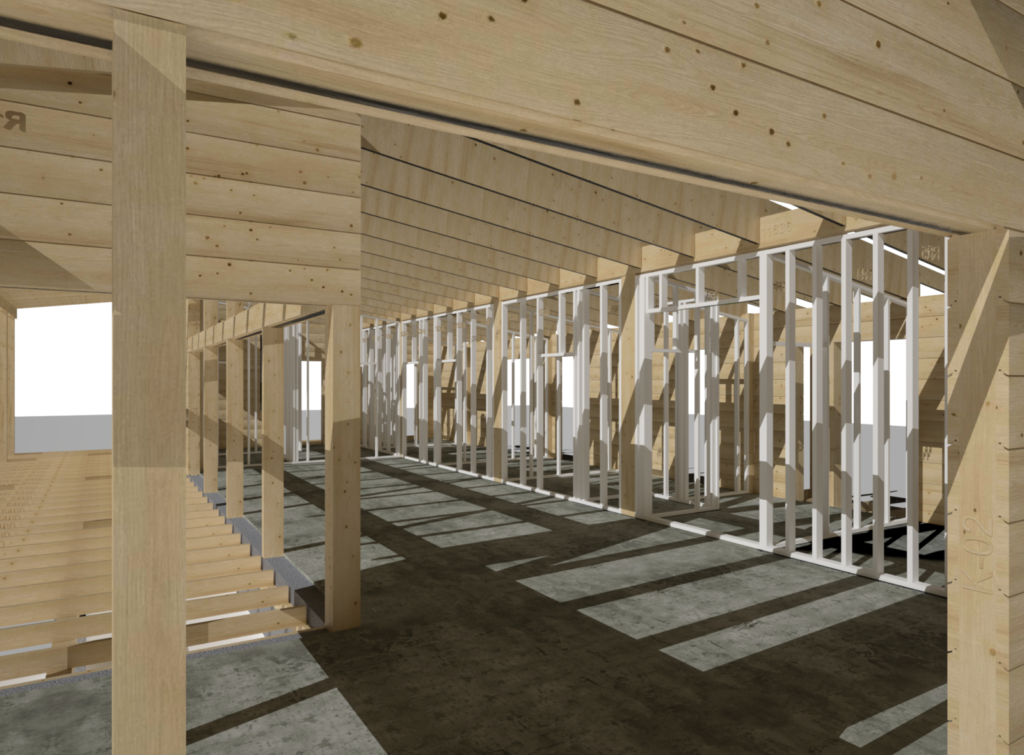

“It’s been great to watch how the industry has developed over the past twenty years. In the early 2000s, many traditional log buildings were designed with traditional cross-corners and decorative log railings and log ends. The advent of non-settling log technology enabled more complex log structures, large glass surfaces, and column-beam structures. This has also demanded more from log design software. The number of different types of machinings has increased enormously and design tools have become more efficient”.

The rise of timber prefabrication

The degree of prefabrication of wooden elements has also increased and continues to increase. Buildings are increasingly built using premade kits where timber parts are manufactured offsite.

“In this model the designer’s responsibility is emphasized, as what you see on the computer screen is what is delivered to the building site. Though prefabrication reduces waste and assembly time on-site, it increases the time spent on getting the design right. This is where software development can step in to save time”.

Mikko reminds us that timber elements offer an amazingly accurate way of building:

“I think that the accuracy of wooden structures is well illustrated by the fact that in large projects that combine log structures with concrete and steel structures, challenges in coordination have been caused by the dimensional accuracy of timber parts compared to other structures!”.

Future timber industry developments

“Recently, there has been a lot of development in the field of quantity calculation automation, and I predict that the next steps in development will be related to the automation of tendering and cost calculations”.

In Finland, changes to the Construction Law will require more detailed plans for a project to be granted a building permit, but Mikko feels that the timber industry already has this on lockdown.

“I think that currently, the timber house industry has been making more accurate 3D models for years than the new law requires. So only the amount of information put into the models will increase.

In the future, climate studies and material specifications will also be required. To produce these efficiently and accurately, accurate modeling with the right materials is paramount. Integrating the model into systems that produce documentation is certainly one area that we will see develop in the near future.

One area for refinement is in the design of smaller houses as HVAC and electrical designers do not currently make their plans in 3D, contrary to information modeling in larger projects. On small house construction sites, it is often challenging to find routes for technology. If MEP modelling was integrated into the initial design model, these problems would have already been solved during the design phase and the exact material quantities would be known. IFC models could also be used to create ready-made MEP penetrations into wooden structures”.

What are you most looking forward to?

Mikko is looking forward to bringing his own unique perspective to the CAD and BIM development team, collaborating with programmers on how to make software work for designers and engineers.

“I look forward to working with coders who can think about the construction industry from a completely different perspective than us designers. A function that I have dreamed of for years and considered completely impossible may become a day’s work for them and a new button will suddenly appear in a familiar design program! I am looking forward to thinking creatively and bringing out all sorts of new ideas. And I encourage other designers to do the same and get in touch with us to see what is possible”.